Enhanced Worker Safety with Automated Video Analytics

Enhanced Worker Safety with Automated Video Analytics

Executive Summary

Worker Safety: A Global Challenge

Ensuring worker safety is a critical but challenging task across all industries. Construction and related fields like Oil & Gas often present elevated risks due to the nature of the work and the environment. Here’s a look at the Enhanced Worker Safety with Video Analytics using data from authoritative sources:

- High Accident Rates: According to the International Labour Organization (ILO), a specialized agency of the United Nations focusing on work-related issues, in 2020, an estimated 2.3 million workers globally succumbed to work-related accidents or diseases. (Source: https://www.ilo.org/global/about-the-ilo/newsroom/news/WCMS_902220/lang–en/index.htm)

- Human Cost: These accidents cause immense human suffering for workers’ families, impacting livelihoods, physical and mental health. Beyond the immediate impact, these tragedies leave lasting emotional scars on loved ones.

- Economic Burden: The ILO estimates that work-related injuries and illnesses cost the global economy an estimated 3.3 trillion USD annually, translating to a significant portion of global Gross Domestic Product (GDP). (Source: https://www.ilo.org/global/about-the-ilo/newsroom/news/WCMS_902220/lang–en/index.htm) These costs encompass medical expenses, lost productivity, disability payments, and training for replacements.

The Need for Automated Video Analytics in Worker Safety

Traditional methods of worker safety monitoring, reliant on manual inspections by safety officers, have limitations that can be overcome with the use of technology:

- Scalability: As construction projects grow in size and complexity, manual monitoring becomes increasingly difficult to maintain effectively across numerous sites. A single safety officer cannot be everywhere simultaneously.

- Limited Coverage: Safety officers can only observe specific areas at a time, leaving blind spots where violations might occur.

- Human Error: Manual observations are susceptible to fatigue and inattentiveness, potentially missing critical safety issues like workers not wearing Personal Protective Equipment (PPE).

Also read about- How LLMs change UI and UX in software engineering

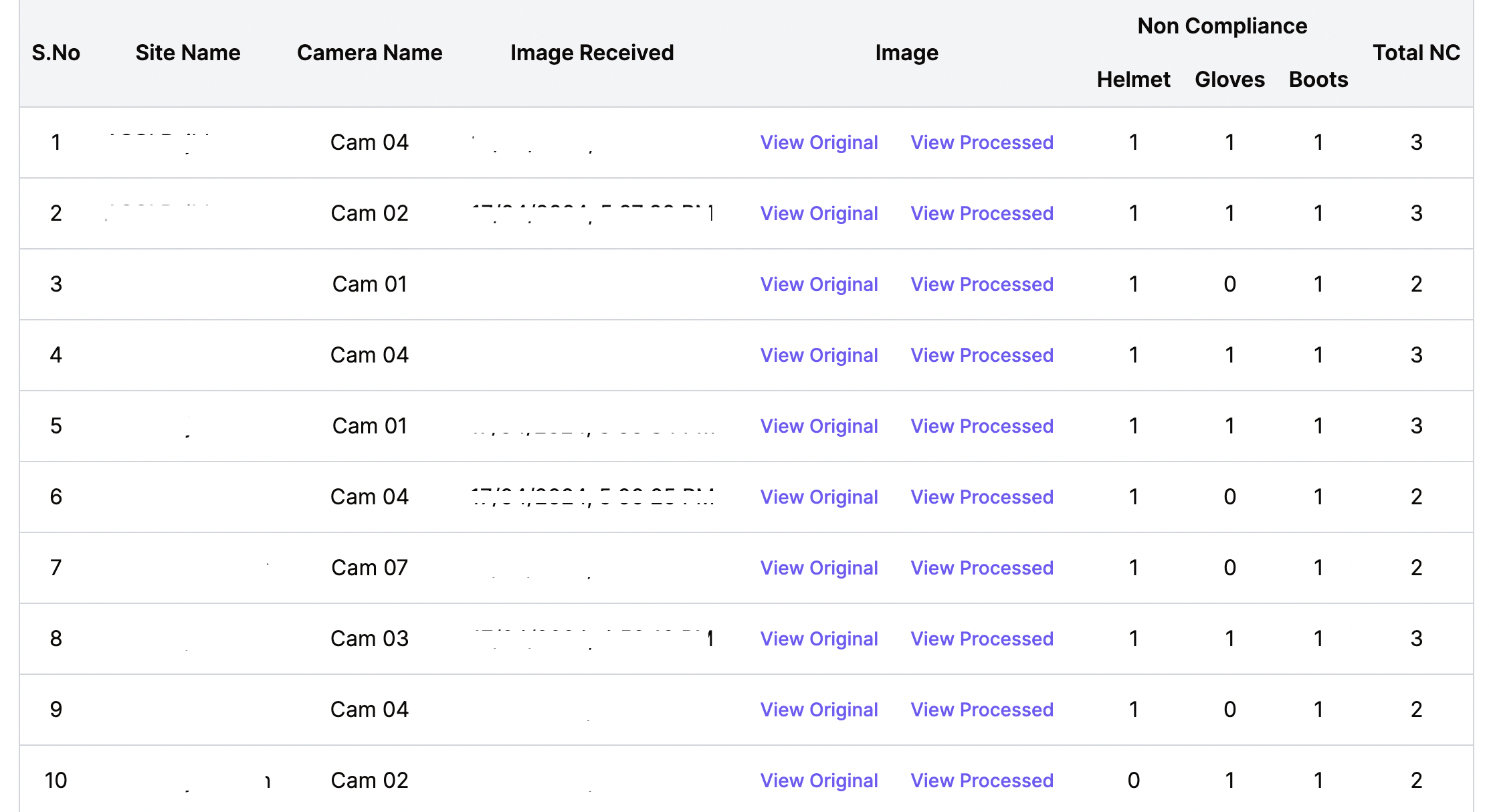

Automated PPE Analytics of the Construction Site for Helmet,Gloves and Boots

This case study explores an implementation by Clarion Analytics for an multi billion dollar Oil & Gas Marketing company in India to leverage computer vision and deep learning for automated worker safety monitoring at its construction sites.

The traditional approach, reliant on manual inspections by safety officers, faced limitations in scalability and real-time coverage. This implementation aimed to demonstrate an centralized video analytics solution to address these challenges and achieve the following objectives:

- Improve worker safety: Ensure adherence to Standard Operating Procedures (SOPs) regarding Personal Protective Equipment (PPE) usage

- Safety Helmets

- Safety Gloves

- Safety Boots

- Safety Harness for working at heights

- Job Area Barricading

- Scaffolding

- Enhance scalability: Effectively monitor worker safety across numerous construction sites as the company expands its operations.

- Gain Deeper insights: Obtain data-driven insights into worker safety compliance patterns to inform targeted interventions and training programs.

Challenges and Traditional Approach

- Manual monitoring limitations: Manual inspections were time-consuming, prone to human error, and couldn’t provide real-time data for comprehensive analysis.

- Scalability concerns: As the company expands, deploying safety officers at every site (remote) becomes impractical and expensive.

- Limited data insights: Lack of real-time data on worker PPE compliance hindered proactive safety measures.

Also read about – OpenVINO 101

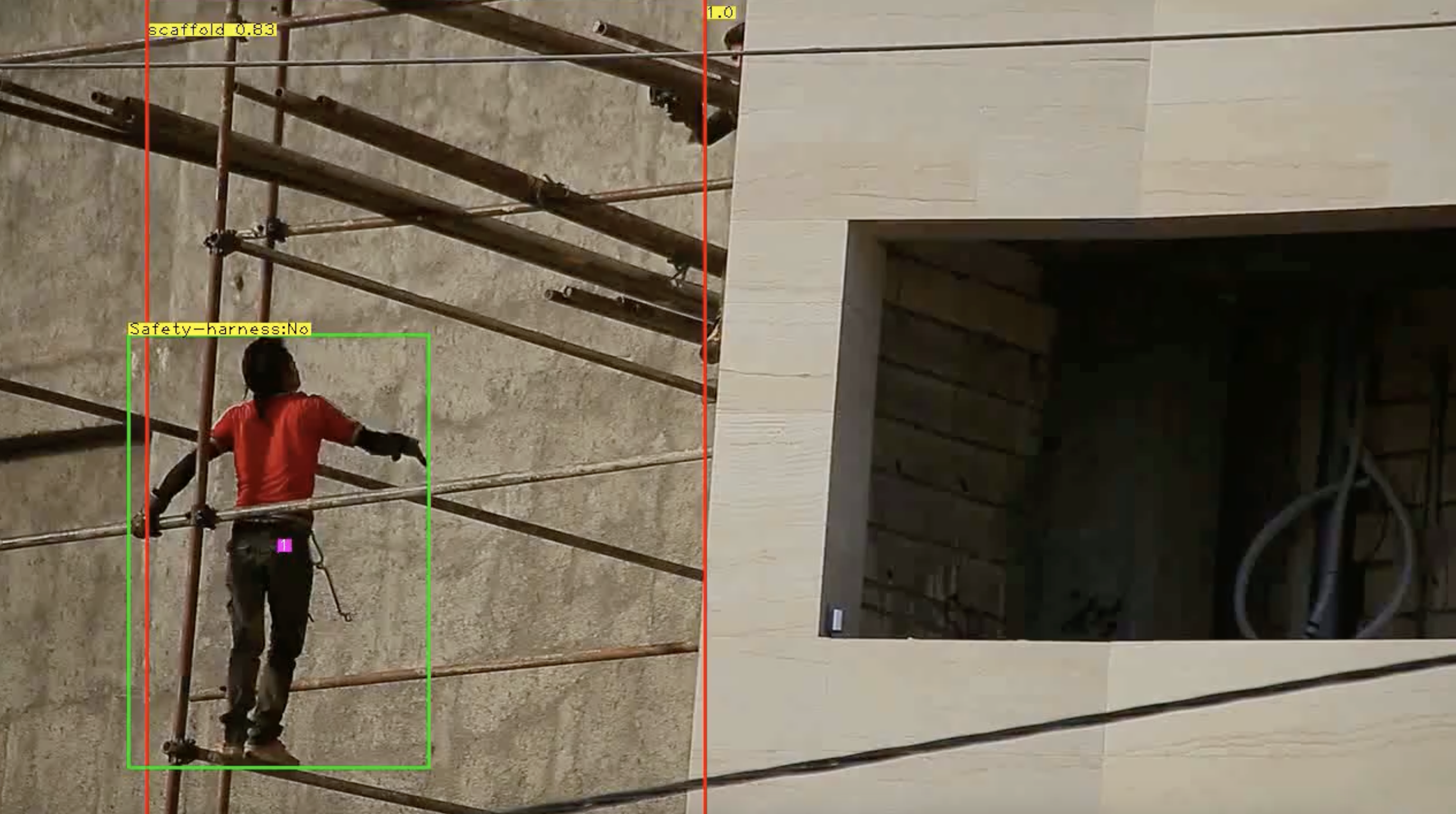

Automated Analytics of the Construction Site for working at Heights

Scaffold and Safety Harness

Technical Solution

- Network Infrastructure: The client had established a video surveillance system with the following specifications:

- Cameras:

- 7 x HIKVISION 4 MP 4mm cameras installed at 8 feet for worker safety gear monitoring.

- 2 x HIKVISION 6 MP 4mm panoramic cameras installed at 20 feet for zone violation monitoring.

- Network: High-speed broadband internet connection.

- Storage: Network Video Recorder (NVR) on-site.

- FTP Storage : IP Cameras configured to push images on Motion Alerts

- Cameras:

- Computer Vision and Deep Learning: Object detection and image recognition techniques were used to identify workers and their PPE usage in video footage captured by the IP cameras.

- YOLO Deep Learning Model: A YOLO deep learning model, known for its speed and accuracy, was trained on a dataset of images labeled with workers wearing or not wearing the required PPE.

- AWS Cloud-Based Processing : While future deployments may explore edge or hybrid processing, this implementation leveraged the cloud for processing.

- The trained deep learning model was deployed on a powerful AWS EC2 g4dn.xlarge instance with NVIDIA T4 GPU’s.

- IP Cameras on detection of Motion (human , vehicle) pushed the images to the AWS EC2 FTP Server (t3.medium) . The FTP server is configured using vsftp daemon.

- A custom script using cron job automated the transfer of images received at FTP server to a designated Amazon S3 storage bucket in the AWS cloud at regular intervals. This ensured efficient data transfer and scalability.

- Celery, a distributed task queue, was used in conjunction with RabbitMQ, a messaging broker, to manage the workload of processing incoming images efficiently from multiple cameras.

- The model was exposed as an API service using FastAPI, allowing Celery and RabbitMQ task queue to execute images against the PPE AI Model and update the MySQL DB for any Non Compliances .

Detailed Report of the Non Compliance

Results and Impact

- Improved Safety Culture: The automated monitoring system fostered a stronger safety culture by promoting worker awareness and accountability regarding PPE usage.

- Reduced Safety Incidents : Near Real-time detection of non-compliance enabled timely corrective actions, potentially leading to a reduction in workplace accidents and injuries.

- Data-Driven Insights Potential: The system’s ability to generate valuable data on worker PPE compliance patterns lays the groundwork for identifying high-risk areas and implementing targeted safety training programs in future deployments.

Also read about – Exploring Deep learning

Outcomes

- Image Processing Volume: Over 400,000 images were analyzed for non-compliance with PPE regulations.

Scalability Validation: The PoC successfully handled a high volume of image data, demonstrating the potential for future site expansion.

Automated Analytics of the Construction Site for Zone Violations

Next Steps: Leveraging NVIDIA Deepstream for Optimization

This site implementation for automated worker safety monitoring using computer vision and deep learning has demonstrated its potential to enhance worker safety and streamline operations for the Oil & Gas Marketing company. Based on the insights gained, the following steps are planned to optimize the solution for future site deployment:

- Leverage NVIDIA Deepstream Framework:

- The current Python-based implementation, while functional, may be computationally expensive on AWS EC2 instances.

- We plan to move the code base to C++ -> NVIDIA Deepstream framework.

- Deepstream is specifically designed for building high-performance streaming analytics applications and leverages the power of NVIDIA GPUs for hardware acceleration.

- This can significantly reduce the processing burden on the EC2 instances, potentially leading to:

- Reduced Infrastructure Costs: A smaller or less powerful EC2 instance might suffice, lowering cloud computing expenses.

- Improved Speed and Scalability: By optimizing processing efficiency, the system can handle a higher volume of image from additional cameras as the company site expands.

Intrigued by the possibilities of AI? Let’s chat! We’d love to answer your questions and show you how AI can transform your industry. Contact Us